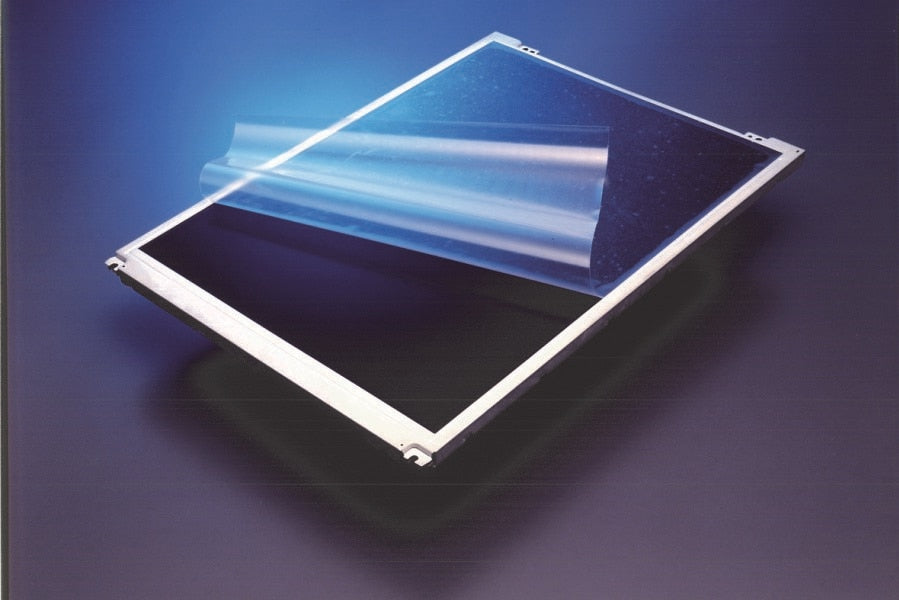

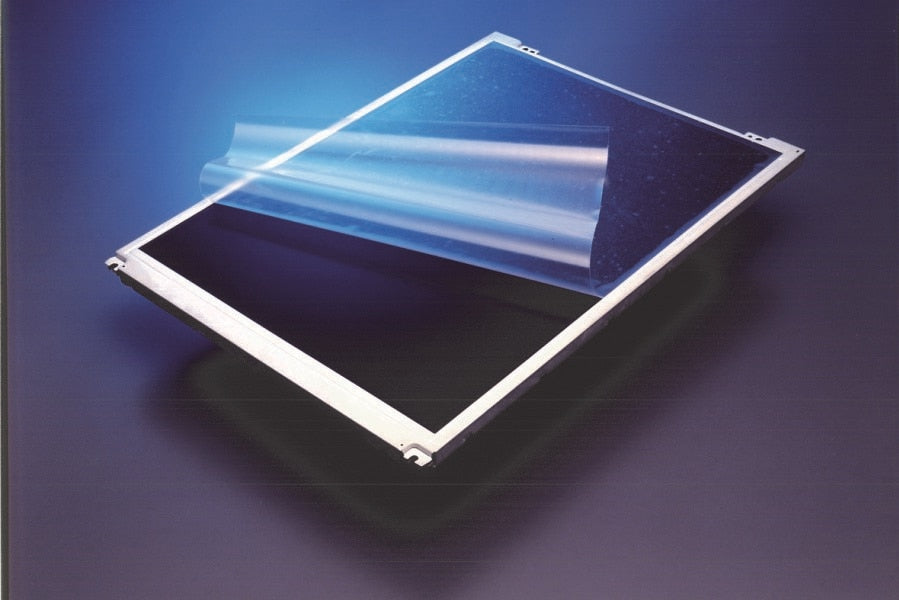

Surface Protective Materials E-MASK™ Series

Masking/surface protection material developed for leading-edge electronics and optical fields.

The excellent qualities of this films have gained these products an outstanding reputation in leading-edge manufacturing facilities in the electronics and optical sectors. These products are used for many purposes, including for masking in the etching processes of electronics material manufacturing, and for protecting LCD components.

Features

[E-MASK™ RP Series]

E-MASK RP Series for the surface protective of optical grade protective film with an antistatic property uses a polyester film as a base material and was produced in a class 1000 clean environment.

[E-MASK™ AW Series]

Polyester-based protective film E-MASK AW series adopt polyurethane adhesive to offer superior wettability, and is best suited for protection of touchscreens during manufacturing process and shipping, as well as for protection of smartphones and tablet PCs during shipping.

[E-MASK™ R/HR Series]

E-Mask R Series and HR Series are polyethylene-based surface protective materials developed utilizing Nitto Denko’s proprietary adhesive synthesis technologies. Both series are especially suitable for surface protective of LCD polarizing films, hard-coat or non-glare treated acrylic plates, and polyester films during processing and transportation.

[E-MASK™ RB-S Series]

E-MASK RB-S Series of surface protective materials developed for optical films such as LCD polarizing film prevents static electricity produced. Offers stable adhesion and easy peeling.

Properties

| Type | Product name | Thickness [mm] |

Max. width [mm] |

Standard length [m] |

Core |

|---|---|---|---|---|---|

| RP | RP207 | 0.059 | 1300 | 200 | Plastic |

| RP301 | |||||

| AW | AW303EB | 0.048 | 1200 | 200 | Plastic |

| R | R-50EP | 0.060 | 1250 | 200 | Plastic |

| R-100 | 0.065 | Paper (Plastic) |

|||

| R-200 | |||||

| R-300 | 0.070 | ||||

| HR | HR6010 | 0.063 | 1310 | 200 | Plastic |

| HR6030 | 0.070 | ||||

| RB-S | RB-100S | 0.045 | 1250 | 200 | Plastic |

| RB-200S | |||||

| RB-300S | 0.050 |

Precautions

- Avoid sunlight and store at room temperature and moderate humidity.

- Do not press too strong when applying. This may cause the end of the tape to peel.

- If applying to surfaces treated with machining oil, degrease the surface carefully. Any remains will be a cause for surface contamination or adhesive residue.

- For use under severe conditions, please test and evaluate the product thoroughly beforehand.

- Painting, plating, etching, or gluing the surface after peeling the tape may be troublesome due to the small amount of residue of the adhesive. Please inspect under actual situations thoroughly before application.

- Painted boards, depending on conditions such as paint baking, may cause the tape to peel uneasily or peel off the paint together. Please evaluate thoroughly beforehand.

- Surface treated boards such as alumite, depending on treatment conditions, may show different properties (peeling) of SPV. Please evaluate thoroughly beforehand.

- Especially for applications against natural substrate (marble stone, lumber, etc.) please contact our sales representative in charge.