When it comes to industrial equipment protection, Devcon Brushable Ceramic coatings are trusted solutions for extending service life and improving performance in harsh operating environments. These high-performance coatings provide excellent protection against erosion, corrosion, and abrasion. But with two main options available – Red and Blue – many engineers and maintenance professionals often ask: Which one should I choose?

In this article, we’ll break down the differences between Devcon Brushable Ceramic Red and Blue, their applications, and how to select the right product for your needs.

What Is Devcon Brushable Ceramic?

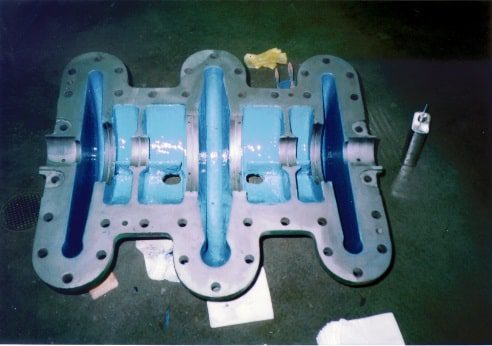

Devcon Brushable Ceramic is a two-component, brush-applied epoxy coating designed to protect metal surfaces exposed to wear and chemical attack. It creates a smooth, protective barrier that not only shields equipment from damage but also improves efficiency by reducing friction and turbulence.

Commonly used in pumps, valves, impellers, tanks, heat exchangers, and pipework, these coatings are an economical way to restore and protect equipment without costly replacement.

Devcon Brushable Ceramic Red

Key Features:

- Designed as a base coat.

- Provides strong adhesion to metal substrates.

- Ideal for surfaces exposed to moderate abrasion and corrosive fluids.

- Typically applied as the first layer in a two-coat system.

- Approved for use in meat and poultry plants

Applications:

- Pump housings and volutes.

- Internal pipe surfaces.

- Tanks and chutes exposed to slurry or corrosive fluids

By forming a strong bond with the metal surface, the Red coating ensures maximum adhesion for subsequent layers, making it an essential foundation in many protection systems.

Devcon Brushable Ceramic Blue

Key Features:

- Designed as a top coat.

- Provides a low-friction, high-gloss finish.

- Excellent resistance to chemical attack and fluid flow erosion.

- Enhances equipment efficiency by reducing drag and turbulence.

Applications:

- Overcoating Devcon Brushable Ceramic Red.

- Surfaces requiring a smooth, fluid-flowing finish (pumps, impellers, pipe interiors).

- Ideal where chemical resistance and efficiency gains are crucial.

The Blue coating is not only protective but also functional – its slick finish minimizes energy losses in fluid-handling equipment, which can translate into operational cost savings.

Red vs. Blue: Which Should You Choose?

The answer lies in how you plan to use the coating:

- For maximum protection – Use Red as a base coat and Blue as a top coat. This combination provides adhesion, durability, and efficiency.

- For general corrosion protection – Red can be used alone or protective layer.

- For efficiency improvements – Blue can be applied over Red or directly onto surfaces where a smooth, low-friction finish is the priority.

In most industrial applications, the two-coat system (Red + Blue) is recommended. It combines the adhesion strength of Red with the slick, protective qualities of Blue for long-lasting equipment performance.

Conclusion

Both Devcon Brushable Ceramic Red and Blue play important roles in equipment protection. Red serves as the reliable foundation, ensuring adhesion and durability, while Blue provides a smooth, chemical-resistant finish that boosts efficiency.

When used together, they deliver a comprehensive protective system that helps industries reduce downtime, extend equipment life, and improve operating efficiency.

If you’re looking to maximize your equipment’s performance and protection, consider pairing Devcon Brushable Ceramic Red and Blue as part of your maintenance strategy.

Leave a comment

All comments are moderated before being published.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.