Corrosion remains one of the most pressing challenges across industrial and engineering fields. It compromises the structural integrity of critical components, drives up maintenance costs, and leads to premature equipment failure. To combat this, corrosion inhibitor coating play a vital role in safeguarding infrastructure, machinery, and parts exposed to harsh environments. By forming a barrier between metal surfaces and corrosive elements such as moisture, oxygen, and chemicals, these coatings act as effective rust-prevention solutions.

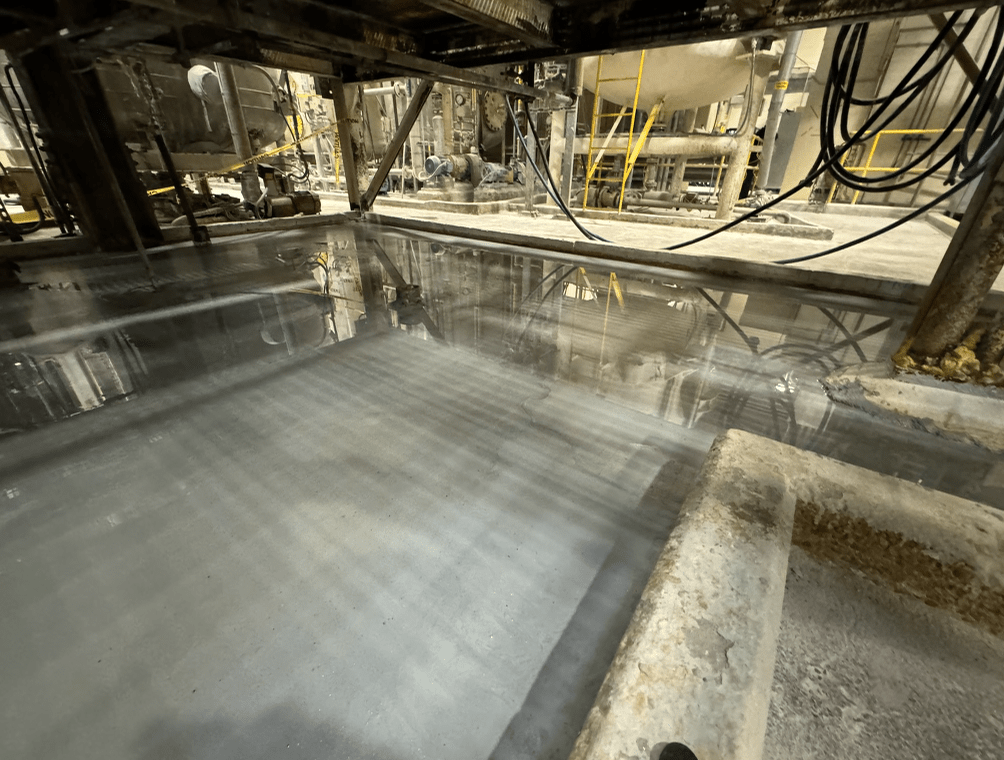

Among the most reliable options are epoxy-based corrosion protection systems like Devcon® Brushable Ceramic and Devcon® Titanium Putty. These products offer exceptional durability, strong adhesion, and superior chemical resistance. Once applied, they create a tough, impermeable layer that blocks the ingress of moisture and aggressive agents—making them ideal for industries including marine, oil & gas, petrochemical, power generation, and manufacturing.

In many applications, epoxy coatings are paired with zinc or other corrosion inhibitors to deliver an added layer of defense against rust and oxidation. Whether used as standalone protection or in combination with inhibitors, these advanced coatings help slow material degradation, extend equipment life, and reduce costly downtime.

Key Applications of Corrosion Inhibitor Coating

Protective solutions such as Devcon Brushable Ceramic and Devcon Titanium Putty are trusted in demanding industries where reliability is non-negotiable. Typical applications include:

- Heat Exchanger Repair – Prevents pitting, scaling, and corrosion, ensuring optimal heat transfer.

- Petrochemical Vessel Protection – Extends service life of pressure vessels and process tanks exposed to corrosive chemicals.

- Pump and Impeller Coatings – Reduces wear and abrasion, improving efficiency and minimizing unplanned shutdowns.

- Marine Equipment Protection – Shields components from saltwater-induced corrosion, prolonging service intervals.

By minimizing wear and protecting against chemical attack, these coatings not only preserve asset integrity but also contribute to higher operational efficiency and reduced downtime.

Sustainability and Cost-Efficiency

The benefits extend beyond corrosion prevention. These advanced coatings support long-term sustainability by:

- Reducing spare parts consumption – Minimizing the frequency of replacements.

- Improving energy efficiency – Ensuring equipment continues to operate at peak performance.

- Lowering carbon footprint – Extending the service life of assets and reducing waste.

In short, investing in corrosion-resistant epoxy coatings translates into long-term cost savings, improved reliability, and more sustainable operations.

Protect Your Equipment Today

If your equipment faces harsh operating conditions or requires urgent metal repair, our team is ready to help. With proven solutions like Devcon Brushable Ceramic and Devcon Titanium Putty, we provide tailored protection strategies to extend the life of your critical assets.

Contact us today to learn how we can safeguard your equipment against corrosion and ensure uninterrupted performance.

Leave a comment

All comments are moderated before being published.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.