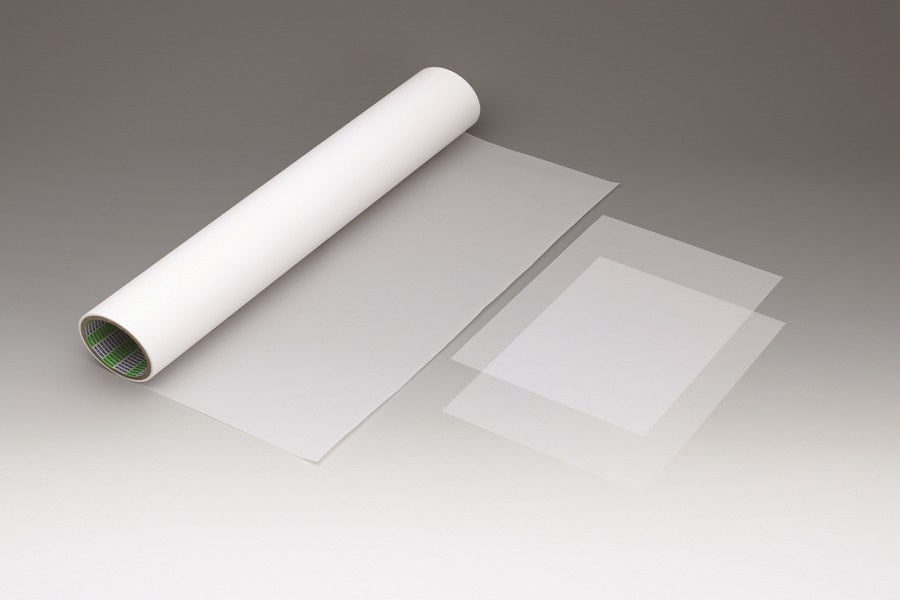

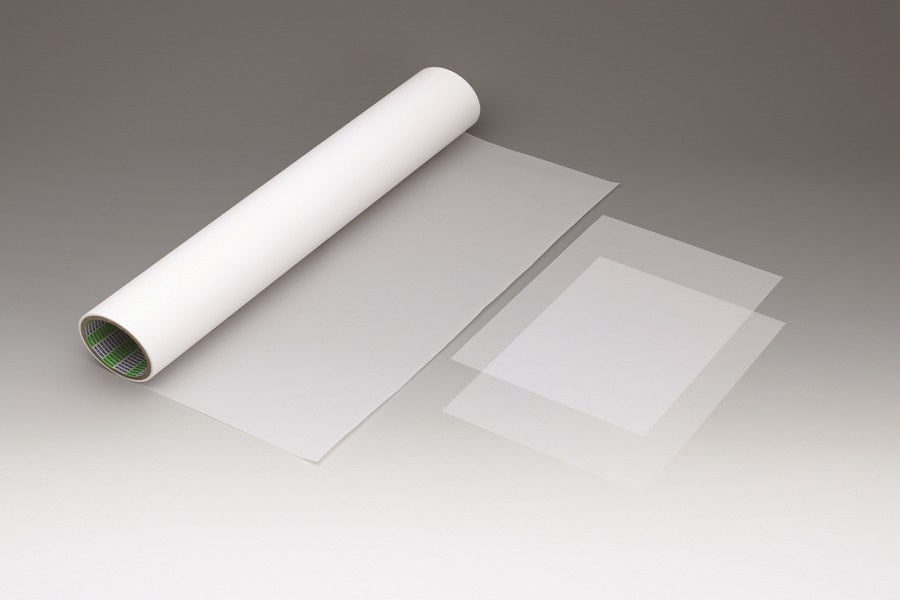

Ultrahigh-molecular-weight Polyethylene Porous Film SUNMAP™

Porous film offers air permeability without changing the characteristics of ultrahigh-molecular-weight polyethylene.

"SUNMAP™" is an ultrahigh-molecular-weight polyethylene porous film developed by Nitto Denko's original technology of special calcinations in which ultrahigh-molecular-weight polyethylene powder is formed into a porous sintered compact, then cut. The porous film provides new characteristics such as air permeability and low friction coefficient while maintaining the superior characteristics of ultrahigh-molecular-weight polyethylene such as chemical resistance, abrasion resistance, and releasability. With excellent processability, it offers and will expand a wide range of applications.

Features

- Porous film of open cell with excellent air permeability and moisture permeability.

- Offers superior sliding property by making ultrahigh-molecular-weight polyethylene porous which has excellent abrasion resistance and low friction coefficient.

- Hardly affected by virtually all the chemicals including acid and alkali with its chemical stability.

- Can be used for heat sealing, punching and for fillers with its excellent processability.

Properties

| Product No. | SUNMAP LC-T |

| Thickness [mm] | 0.5 |

| Average pore size [µm] | 17 |

| Air permeability [sec/100cm3] | 1.4 |

| Porosity [%] | 30 |

| Tensile strength [Mpa] | 12 |

| Elongation [%] | 90 |

| Hardness [Shore D] | 48 |

| Surface roughness(Ra) [µm] | 2.0 |

| Dynamic coefficient of friction | 0.1 |

[Remarks]

- * The above values are sample observed values, not the guaranteed performance.

Applications

- Absorption/fixing of ceramic green sheet.

- Fixing when cutting LCD panel, cutting glass/ceramic substrates

- Fixing during FPC board screen printing

- Fixing during semiconductor wafer dicing

- For polishing and fixing lenses