As the world accelerates toward cleaner energy systems, hydrogen is emerging as a cornerstone of global decarbonization strategies. Its abundance, high energy density, and carbon-free combustion make hydrogen an ideal candidate for replacing fossil fuels in many industrial and transportation applications. However, one of the biggest challenges facing hydrogen adoption is ensuring leak-free storage, transport, and utilization due to the molecule’s exceptionally small size.

The Challenge of Hydrogen Leakage

Hydrogen’s tiny molecular structure allows it to escape through microscopic gaps in metal fittings and threaded joints—areas where even the most precise machining can leave surface imperfections. Leakage not only reduces efficiency and increases operational costs but also poses safety risks due to hydrogen’s flammability. To counter this, engineers have traditionally relied on expensive connection methods, such as seal welding or specially designed fittings, which significantly raise installation and maintenance costs.

Henkel’s Innovative Solution: LOCTITE® Sealants and Sealing Cord

Recognizing the need for reliable and economical sealing technology, Henkel’s engineering team conducted a comprehensive study to test the performance of anaerobic thread sealants and thread sealing cords under hydrogen service conditions. Their findings highlight how LOCTITE® products—specifically LOCTITE® 567, LOCTITE® 577, and LOCTITE® 55—deliver effective, durable, and cost-efficient sealing for hydrogen systems.

Anaerobic thread sealants, such as LOCTITE® 567 and LOCTITE® 577, cure in the absence of air to form a thermoset plastic that fills every microscopic gap between metal threads. This creates a 100% contact seal, eliminating potential leak paths while providing resistance to vibration, temperature fluctuations up to 200°C, and pressures up to 31 bar (450 psi). LOCTITE® 55, a non-hardening sealing cord, provides a flexible option for applications requiring fine adjustments before final assembly, effectively sealing up to 10 bar (150 psi).

Proven Performance Through Testing

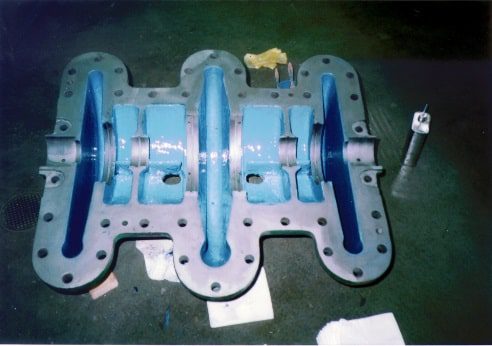

Henkel’s tests were conducted using stainless steel NPT and BSPT threaded assemblies to simulate real-world hydrogen transmission systems. Using the pressure drop method, the study measured leakage rates under various pressures. The results were unequivocal—no detectable pressure drop occurred across all test samples, confirming complete leak prevention.

Furthermore, all three products have received Kiwa AR 214 certification for hydrogen sealing applications, ensuring compliance with stringent European standards.

Supporting a Hydrogen-Powered Future

With global hydrogen demand expected to grow exponentially by 2050, safe and reliable infrastructure will be critical to the energy transition. Henkel’s LOCTITE® solutions offer manufacturers and energy companies a way to confidently design hydrogen-ready systems without the high costs associated with seal welding or specialized fittings.

By ensuring tight, durable seals in pipelines, valves, and other threaded connections, Henkel’s hydrogen-ready sealing solutions enable industries to build cleaner, safer, and more sustainable operations.

FAQs – LOCTITE® Solutions for Hydrogen Leak Prevention

Q1: Why is hydrogen leakage such a serious issue?

A: Hydrogen molecules are extremely small—much smaller than air or water molecules—so they can escape through microscopic gaps in metal threads and fittings. Leakage not only results in energy loss and reduced efficiency but also creates serious safety hazards, as hydrogen is highly flammable and forms explosive mixtures with air.

Q2: How do LOCTITE® thread sealants prevent hydrogen leaks?

A: LOCTITE® anaerobic sealants like LOCTITE® 567 and LOCTITE® 577 cure in the absence of air to form a solid thermoset polymer that completely fills all microscopic voids between metal threads. This ensures a 100% contact seal, effectively eliminating leak paths—even under vibration, temperature swings (up to 200°C), and pressures up to 31 bar (450 psi).

Q3: What is LOCTITE® 55 and how is it different from the liquid sealants?

A: LOCTITE® 55 is a non-hardening thread sealing cord, making it ideal for connections that may require repositioning or fine adjustment before final tightening. It provides excellent sealing performance for pressures up to 10 bar (150 psi) and is especially user-friendly in assembly lines or field service applications.

Q4: Were these products tested specifically for hydrogen applications?

A: Yes. Henkel performed rigorous testing on stainless steel NPT and BSPT threaded assemblies, simulating real-world hydrogen systems. Using the pressure drop method, no leakage was detected in any of the test samples across various pressure ranges.

Q5: Can these LOCTITE® products replace traditional sealing methods like seal welding?

A: Yes. LOCTITE® thread sealants offer a more cost-effective and flexible alternative to expensive methods like seal welding or custom hydrogen-rated fittings. They reduce installation time, allow for easier disassembly if needed, and eliminate the need for heat or specialized tools.

Q6: What types of systems or industries can benefit from using these LOCTITE® sealants?

A: Any hydrogen-based infrastructure or system—including pipelines, compressors, valves, fuel cell components, and hydrogen refueling stations—can benefit. These products are also relevant in industries such as energy, automotive, aerospace, and industrial manufacturing where hydrogen is being integrated.

Q7: Are these products compatible with stainless steel and other common materials used in hydrogen systems?

A: Yes. The tested LOCTITE® sealants are fully compatible with stainless steel, brass, aluminum, and other metals typically used in hydrogen applications.

Q8: What is the shelf life of LOCTITE® 567 and 577?

A: When stored properly in unopened containers at recommended temperatures, these products generally have a shelf life of 24 months. Always refer to the product’s Technical Data Sheet (TDS) for specific storage guidelines.

Leave a comment

All comments are moderated before being published.

Situs ini dilindungi oleh reCAPTCHA dan berlaku Kebijakan Privasi dan Persyaratan Layanan Google.